by Professor String

by Professor String |

Tuning Lubricants: Can they damage your guitar? |

|

The short answer to this question is: Yes! We are going to show some of the pitfalls of these products in this article. Over the past few years, the guitar and bass string market has seen a number of various manufacturers start to offer lubricants for a string’s fulcrum points. For you non-techo-speaking-geeks, the fulcrum is a support or point of support on which a string vibrates. This is typically on the bridge saddle or nut region of the guitar. The lubricant is supposed to reduce the friction caused by a string sliding across the nut or saddle. When does a string move across the nut or saddle? It happens whenever we bend a string; tune a string, press on the string, or whenever the guitar neck flexes. In theory, it can help prevent string binding whenever a nut slot is extra tight. It also can help prevent the windings on a string from binding on a sharp saddle edge. For those of you with sharp saddle edges and narrow nut slots, you can see a string suddenly jump in pitch on a digital tuner as you turn the tuning peg. In some cases, you might actually hear the string make a sudden pop or creak noise.

|

|

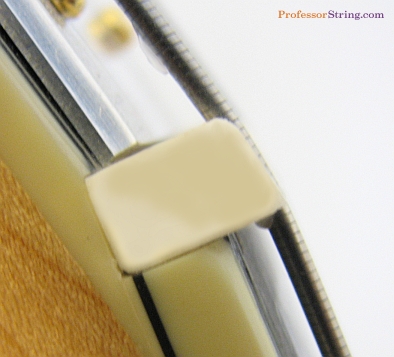

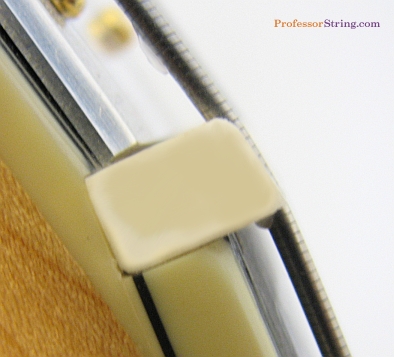

Tuning lubricant being applied on the saddle. |

There are some problems that can arise from using these tuning lubricants. We are going to get into that discussion, but first let’s summarize the types available. There are four main types of tuning lubricant used today by guitar technicians: petroleum based gel, wax, oil, and graphite. As with anything else, each has its pros and cons.

1. Petroleum Based Gel – These have become popular as some manufacturers have developed clever applicators and dispensers for pinpoint applications. The lubrication is a clear jelly that prevents runny messes. Vaseline, with a toothpick applicator is a good alternative if you don’t want to drop the big bucks on the expensive stuff.

Pros: Easy to work with applicators

Cons: Expensive. Some contain penetrating properties that will discolor or cause plating to flake off.

2. Wax – Dental tape that is waxed is perfect for getting into those tight nut slots. Some technicians like to use a piece of twine rubbed over candle wax instead of dental tape. Either one accomplishes the same effect.

Pros: Low buck and readily available at most stores. Wax will not discolor components.

Cons: The wax tends to break down when exposed to higher temperatures, leaving no lubricity.

3. Oil – Common household oils or mineral oils are good choices. Use very sparingly as too much will create a mess. Be careful not to use penetrating oils as you could end up with discoloration or chrome plating flaking off. Some technicians run a small drop down a needle as an applicator.

Pros: Low cost and easy to find. Excellent anti-friction properties.

Cons: Very messy. Difficult application. Penetration properties can ruin components.

4. Graphite – This has been a popular choice for many years. A sharpened pencil tip or mechanical pencil will get the graphite into tight string channels on the nut. The lubricity properties are not as robust as the petroleum based lubes, but it does help.

Pros: Low cost and easy to use.

Cons: Lubricity properties can be limited and not as effective across a sharp string saddle.

Avoid Penetrating Properties

We mentioned earlier some of these tuning lubricants can have penetrating properties. Penetrating oils and lubricants should be avoided as they can penetrate into a guitar’s components. Unfortunately, some of the more popular (and expensive) petroleum gel based lubricants can be very penetrating. Be careful in which one you select. We ran an experiment to find out how a tuning lube could adversely affect the nut of a guitar neck. The results were amazing, and very concerning. Here is what we found…

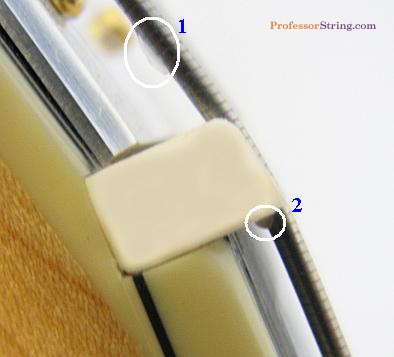

We applied a tiny droplet of a popular tuning lubricant to the string and nut of the guitar.

|

Day 1 In this figure we have illustrated where excess lubricant still remains. |

|

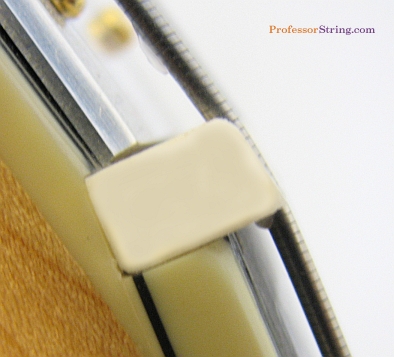

Day 2 For the next few days we took still frame photos of the nut. After the first two days, we started to see a slight amount of discoloration. This discoloration was being caused by the lubricant saturating into the nut material. |

|

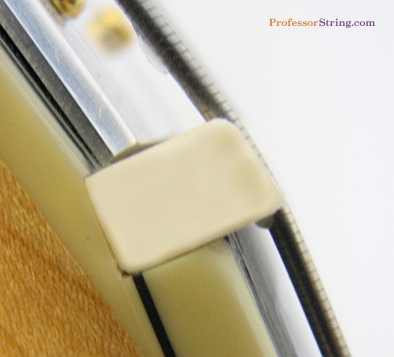

Day 5 Discoloration becomes more apparent. |

|

Day 8 Penetration continues. |

|

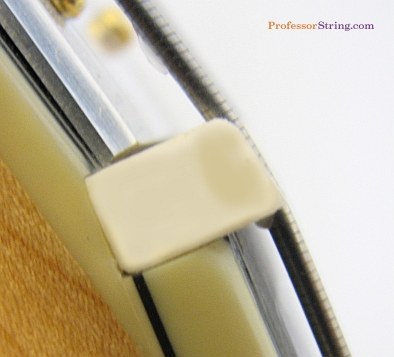

Day 11 The majority of the nut has become discolored by the lubricant. |

|

Day 14 We kept taking still frame photos and after two weeks, the nut was completely discolored and saturated with the lubricant. This was much more than we expected. |

Here is the question: Is this harmful?

At the very minimum, the nut has been discolored, which is a cosmetic issue some guitarist might not like. Long term, you can expect the aging of this component to be altered. Penetrating oils and lubricants have been known to soften materials like wood and plastic…a possible issue for a plastic or bone nut. This raises some more questions…

Do you think the string lubricant company would fix our replace our guitar? There is no warranty on their packaging.

Would you want this to happen to your pride and joy guitar?

Conclusions

From our experiment, we have seen the pitfalls with tuning lubricants. Some petroleum based tuning lubricants can have penetrating properties that can harm your guitar. Lubricants such as wax and graphite are fairly passive, but limited in their effectiveness when compared to their petroleum based lubes. Some tuning lubricants can be very expensive for the small amount you get in a dispenser. If you use a petroleum based tuning lubricant, find out if the manufacturer has a guarantee against instrument damage from their product. Tuning lubes can be a nice tweak to your guitar’s tunability. Be wise when selecting which one will work best for you.

Do you have some thoughts about this article or the subject? Share it with everyone on the Professor's Forum.

|