Strings 101

- Coated Guitar Strings

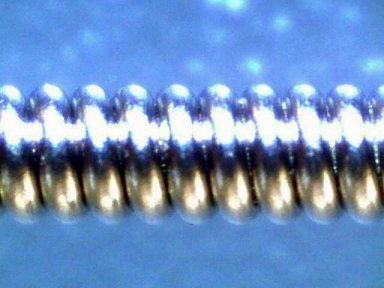

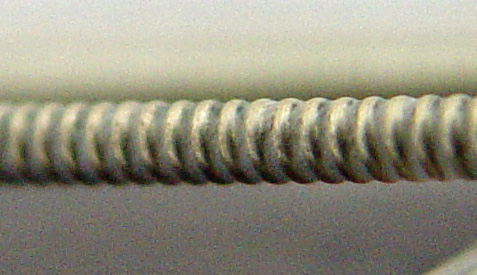

Coated guitar strings are perhaps one of the latest and fastest growing developments in guitar strings and bass strings. To create a coated guitar string, the process involves taking a wound guitar string and applying a polymer (often Teflon) coating on it. Keep in mind the plain strings are not coated in coated string sets. The idea behind coating a guitar string is to prevent string corrosion over time. Corrosion on guitar strings is common, and is attributed to moisture and skin protein deposits that contain salt. The polymer coating allows string manufacturers to claim reduced finger squeak, reduced fret wear, and better tuning capability. It also gives them the ability to apply colored polymer to achieve the appearance of colored strings. Applying the polymer coating is not a simple process. The trick is getting a very thin microscopic layer of polymer uniformly across the entire length of a string. An uncoated string is shown in Figure 1. In Figure 2 below, a coated string is shown. You will notice the coated string in Figure 2 has the gaps in the windings filled with polymer. This polymer serves as a protective layer against the element that create string corrosion. Before you buy a set of coated guitar strings or bass strings, be sure to read The Five Things You Must Know About Coated Guitar Strings.

|

Figure 1. Uncoated String

|

|

Figure 2. Coated String |